Stokers

REI provides research and consulting services for a variety of stoker applications. Projects have focused on evaluating stoker performance, emissions and operating challenges. REI provides modeling analyses for both spreader and mass-burn designs with an emphasis on developing practical solutions for a range of issues including the following:

Spout/spreader design

Overfire air injection design

FGR system design

Water injection for thermal NOx control

NOx and CO emission evaluations

Bed fragmentation, re-entrainment, and carbon-in-flyash

Cinder re-injection impacts

Extent of combustion in bed

Deposition and corrosion evaluations

Evaluations of temperature/oxygen concentration/residence time criteria

Through a strategic relationship with Detroit Stoker Company, REI has developed unique tools for application to spreader stokers. In addition to the applications listed here, REI continues to develop expertise in new areas. If your application is not among those listed, please contact us to discuss appropriate ways we may be able to work together.

Project Summaries

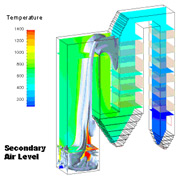

WOOD-FIRED STOKER BOILER

REI’s combustion simulation tools, along with validated descriptions of Detroit Stoker Company spreaders, was used to create an accurate description of fuel location and reaction in a stoker boiler fired with waste wood. This information was integrated with the detailed model of the boiler to determine whether or not combustion products had experienced sufficient residence time (1) under oxidizing conditions and (2) at temperatures above 850 degrees Celsius to achieve design goals.